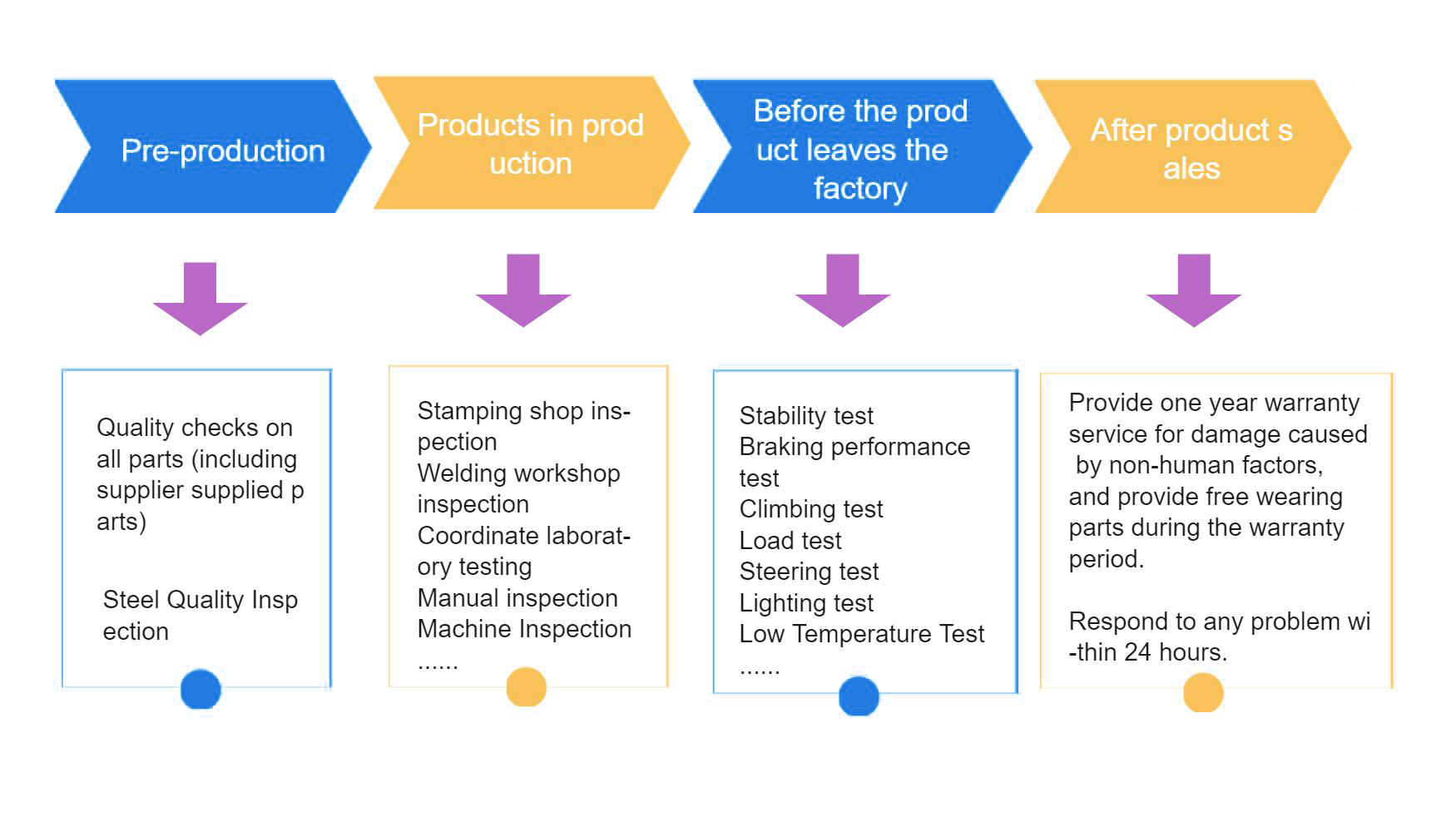

Safety and high quality are our unchanging promises to our customers. We attach importance to the safety and quality management of our products, and strive for their ability to maximize their value in the hands of our customers. For this reason, we conduct strict and comprehensive tests on all products we produce, from parts to complete vehicles, and from pre-production to post-production.

l In addition to in-house production, we also source some parts from globally recognized brands such as Toyota and Cummis, and before production, we will conduct quality checks on all parts to test whether their performance and strength meet the standards.

l During the production process, we will first carry out steel inspection and acceptance in the stamping workshop, after proofreading the material composition and model, check to ensure that the steel raw materials used for production are free from defects. In the process of product articulation, welding will be carried out by machine welders in the welding workshop, and at the same time, real-time monitoring by automatic robotic arms to ensure that all welding points, riveting points and structural adhesive joints can all be effectively joined. In the production line, each process will be carried out before the next step of the operation of a double quality inspection, including machine and manual. During the assembly process, the quality inspectors will compare the standard gauges to ensure that the manufacturing apertures, dimensions and accuracy are not in error. Key semi-finished parts will be put into the coordinate laboratory for precision testing to ensure that the specifications meet the actual needs.

l After the products are completed and assembled, they need to undergo pre-factory quality testing at the testing yard, which includes a series of tests such as stability, brake performance, loading performance, driving performance, lighting and so on.For the key performance and structure of braking, traction performance, hill climbing, hydraulic system, etc., we strictly follow the national and industry standards to make constraints on product quality.At present, LAITUO has an independent vehicle testing site equipped with various advanced testing instruments, which can meet the key components and vehicle performance test requirements of loaders, log loaders, forklift loaders, motor graders and other industrial vehicles, and provide customers with stable and reliable products.

l We offer a one-year warranty on sold products in the event of non-human-caused damage, free of charge during the warranty period to provide wearing parts.If you are not satisfied with any details of our company's sales and service, please feel free to contact us. We will respond within 24 hours and do our best to solve the problem for you.